Porcelain Insulator News

by Elton Gish

Reprinted from "Crown Jewels of the Wire", April 2003, page 38

Dry process porcelain is the cheapest type of porcelain to make. It is also

the poorest quality for electrical use due to the inherent porous nature. Some

dry process porcelain is high quality and difficult to distinguish from wet

process porcelain even at the firing rest or if a chip exposes the porcelain.

Dry process porcelain was made from clay with a low water content. The clay was

flaked to a consistency similar to saw dust. An adequate portion was the put in

a two-part mold and pressed under very high pressure to form the desired shape.

Usually mold lines are present if the glaze is not too thick. Sometimes extra

care was provided by wiping off the mold lines with a wet sponge. Another basic

difference is the profile of the insulator was not trimmed in as with wet

process insulators. The profile with side wire groove was formed in the mold and

you can usually see a mold line across the wire groove. The mold line is not

always an indicator of dry process porcelain. Fred Locke and Pittsburg often

used two-part molds to make wet process insulators.

Dry process porcelain

afforded a way to make difficult shapes because it used two-part molds. Most

knobs, cleats, spools, etc. (call standard porcelain) were made by the dry

process. The voltages were low and adequate electrical protection was afforded.

However, Pittsburg cataloged a spiral groove insulator identical to CD 147 made

of wet process porcelain. However, none have ever been found. Macomb made dry

process insulators in four-part molds. The crown was one part, two parts for the

profile, and a fourth part to form the base. A characteristic mold line around

the base is indicative of Macob manufacture.

Most companies either made dry

process or wet process insulators. Thomas wanted to give their customers a

choice. They made a low voltage line of dry process insulators as an alternative

to their higher quality and more expensive wet process insulators. This was

obviously very successful because there are many styles of low voltage dry

process Thomas insulators still in service and showing up all over the country.

Thomas even went after the foreign market for low voltage insulators. I doubt

they were very successful because foreign customers were use to high quality wet

process insulators, which did not have mold lines, surface imperfections,

obvious porous porcelain, and an overall cheap appearance. This did not

discourage Thomas from offering no less than seven styles. Since none have been

reported found outside the U. S., we have no way of knowing how successful they

were. Jerry Turner and his family dug in the Thomas dump many years ago and found a lot of broken foreign style insulators. Note

that all of the foreign style insulators discussed here have a very small

foreign style pinhole, so they cannot be confused with insulators made for the

U. S. market with the basic 1-inch pinhole.

Not all porcelain Gingerbread Men

are made alike. Thomas made that style, too. Besides finding broken specimens at

the Thomas dump, we recently uncovered further evidence in the form of five

styles offered in the 1925 American Jobbers Supply Co. catalog. At first glance,

it appeared that the five styles were offered were not made by Thomas. The

catalog states, "Standard Electric Porcelain manufactured for us by

Illinois Electric Porcelain Co., Macomb, Illinois:'

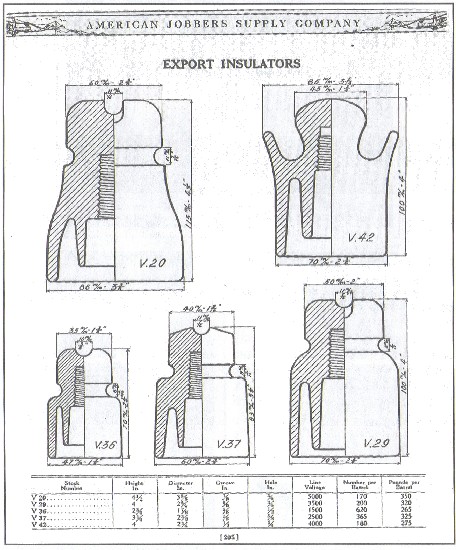

Page from the 1925 American Jobbers Supply Co. catalog.

The U. S. style pin-types in

the catalog are obviously Illinois manufacture, but the single page of foreign

styles use a different catalog numbering system with a "V" before the style number. This

probably indicates a different manufacturer. The two foreign styles found at the

Thomas dump match exactly to the dimensions shown on this page, which indicates

strongly the catalog styles were made by Thomas. Furthermore, Jack Tod believed

Illinois phased out dry process insulators in the 1920's after converting to wet

process manufacture in 1915. It is more likely that they phased out dry process

before 1920 preferring to concentrate on wet process. Thomas may have tried to

switch their dry process manufacturing to foreign styles when the U. S. market

for dry process pin-types fell off dramatically by 1920. It does appear that

most U. S. dry process insulators were made prior to 1920 with Thomas being the

primary supplier.

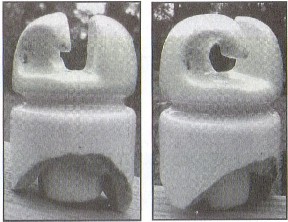

Thomas V29 and V42 styles found at the Thomas dump.

V29 and V42 were the most common style found at the Thomas dump. Whole

undamaged specimens of V42 have been seen at insulator shows, which probably

originated from the dump. The two smaller styles, V36 and V37 have not been

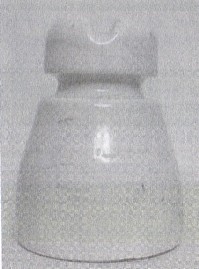

reported. Robin Harrison reported V20, which he always thought was foreign made

even though it appeared to be made of dry process porcelain.

Robin Harrison's Thomas V20.

Dennis Stewart and his father found an odd twist-lock style, too, at the

dump. Essentially all foreign porcelain insulators are wet process. If you find

a foreign style that was made of dry process porcelain, chances are Thomas made

it.

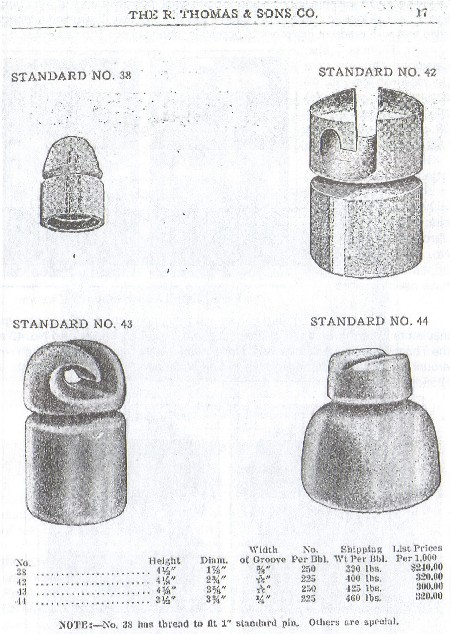

Thomas also cataloged. two standard porcelain styles (No. 42 and No. 43),

which are twist-lock styles. The No. 38 style is actually the U.S. style, U-143

and U143A. Thomas cataloged this style (#1032) in their normal catalog without

reference to it being one of the standard porcelain styles. No. 44 has a foreign

appearance but none have been reported.

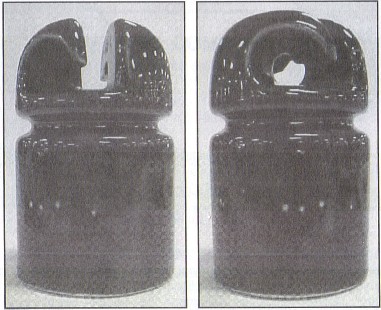

Intricate twist-lock style made by Thomas

Numbering of standard porcelain styles approached 100 and pin-type insulators

were the exception. Dennis Stewart found a white glazed No. 43 at the Thomas

dump. A near perfect No. 43 with a dark brown glaze was shown around at the 2002

Springfield show last November by Alan Hohnhorst. A Standard No. 42 has not been

reported.

Brown glazed Thomas foreign style twist-lock insulator

from the collection of

Alan Hohnhorst.

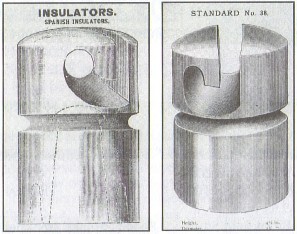

Another odd thing to note is the 1901 Western Electric catalog of Standard

Porcelain shows No. 38 to be identical to the Thomas No. 42. And the Western

Electric No. 42 and No. 43 split nail-knobs. This doesn't sound very "standard". Other companies also made the Thomas Standard No. 42.

at the factory was dated April 20, 1908, and called for a white glaze. The

twist-lock top was more similar to the Thomas No. 43.

All this about U. S. made

foreign dry process insulators is a very interesting and a little researched

part of our hobby. I would like to hear from anyone with additional catalog

information or photographs of specimens.

Spanish insulator shown in the 1894 Walker & Kepler catalog. (Left)

From

the 1901 Western Electric catalog. (Right)

|